One of the major benefits of truckload shipping is the ability to tailor the truck exactly to your needs using extensive equipment options. Here we will take a look at 3 of the more popular pieces of equipment available for your truckload moves. Dry Vans are the most common form of truckload shipping and is the option best used with standard packaged freight that does not need to be temperature controlled. Refrigerated trucks, generally known as reefers, are used to transport temperature-sensitive goods. Flatbed trailers are used to haul shipments of large, heavy, over-sized loads that cannot easily fit or load within a dry van. It has no sides or roof which allows for accessible loading from the top, side or rear of the trailer.

Common FLT Specifications

Please Note: All truck specifications and dimensions are approximate and are to be used only as a guide. Axle configurations and manufacturers’ specifications may vary.

| Specifications | Dry Van | Reefer | Flatbed* | |||

| 48 Foot | 53 Foot | 48 Foot | 53 Foot | 48 Foot | 53 Foot | |

| Interior Dimensions: | 47’4” L x 8’6” W x 9’2” H | 52’4” L x 8’6” W x 9’2“ H | 46’6” L x 8’2” W x 8’8“ H | 52’2” L x 8’2” W x 8’8“ H | 48’ L x 8’6” W | 53’ L x 8’6” W |

| Door Dimensions: | 8’2” W x 9’2” H | 8’2” W x 9’2” H | 8’ W x 8’7” H | 8’ W x 8’7” H | – – – | – – – |

| Floor Space: | 389.81 sq. ft. | 433.13 sq. ft. | 379.75 sq. ft. | 426.03 sq. ft. | 408 sq. ft. | 45.50 sq. ft. |

| Usable Capacity: | 3,000 cu. ft. | 3,800 cu. ft. | 3,291.16 cu. ft. | 3,692.24 cu. ft. | – – – | – – – |

| Tare Weight (empty): | 10,850 lbs. | 15,000 lbs. | 14,500 lbs. | 15,500 lbs. | 13,430 lbs. | 15,000 lbs. |

| Max Payload: | 45,000 lbs. | 29,000 lbs. | 44,000 lbs. | 43,500 lbs. | 45,000 lbs. | 48,000 lbs. |

| Max # of 48” x 40” Pallets |

24 or 28 turned** |

26 or

30 turned** |

22 or

26 turned** |

24 or

28 turned** |

24 unstacked / 48 stacked | 26 unstacked / 52 stacked |

| Max # of 42” x 42” Pallets | 26 | 30 | 26 | 28 | 26 unstacked / 52 stacked | 30 unstacked / 60 stacked |

*For flatbed trucks, a legal load must not exceed 8’6” high, 8’6” wide and 48’/53’ long.

**Figures are based upon using 4-way pallets, which allows the forks of a forklift to enter on all four sides.

Quick Reference Guide

Use this simple chart to help you plan your truck load.

| Packaging Type | Dimensions | 48′ Dry Van | 53′ Dry Van |

| Standard Pallet | 48” × 40” | 24 | 26 |

| Standard Pallet | 42” × 42” | 26 | 30 |

| Drum | 48” × 48” | 24 | 26 |

| Drum, Chemical | 44” × 44” | 26 | 28 |

| Chemical, Beverage Container | 48” × 42” | 25 | 27 |

| Chemical, Beverage Container | 36” × 36” | 32 | 34 |

| Dairy Crate | 40” × 40” | 28 | 30 |

| Automotive Crate | 48” × 45” | 24 | 26 |

| Beverage, Paper Crate | 48” × 36” | 24 | 26 |

| ISO Container | 35” × 45.5” | 24 | 26 |

| Retail Boxes | 48” × 20” | 60 | 65 |

Calculating Freight Volume

If you are shipping non-palletized freight, you will need to determine the freight volume of the shipment in order to arrange for the most appropriately sized truck. Freight volume is the product of the length, times the width, times the height, times the quantity (number of items) to be loaded.

(Length x W x H) x Quantity

Step 1: Using a tape measure, determine the length, width, and height of the carton, box, or item. For instance, you have a shipment which includes 450 boxes of equal size and weight. The boxes are each 24 inches long, 24 inches wide, 18 inches high, and weigh 30 lbs.

Note: When calculating the volume of cylindrical packages, it is best to check with the carrier to see if they square the circle.

Step 2: Multiply the length, width, and height of a single box to determine the volume in cubic inches. Using this example, we get 4,320 cu. in. of volume per box.

24 x 24 x 18 = 10,368

Step 3: Convert the cubic inches to cubic feet by dividing the total volume of cu. in. by 1728. For this example, we get 6 cu. ft.

10,368 ÷ 1728 = 6

Step 4: Multiply the number of boxes (quantity) by the volume of a single box. In this example, the total freight volume is 3,000 cu. ft.

450 x 6 = 2,700

Step 5: If your shipment includes a variety of different shapes and sizes being loaded (batches), simply repeat the formula for each size and then add the batch volume totals together to calculate the overall freight volume for the entire shipment.

Step 6: Calculate the overall weight of the payload (the total weight of the cargo) by multiplying the quantity by the weight of each item to be loaded. Using this example, the total payload weight is 3,000 lbs.

450 x 30 = 13,500 lbs.

Determining Load Capacity

Now we know that the total capacity (freight volume) for this shipment is 2,700 cu. ft. and the total weight is 13,500 lbs. The next step is to translate that capacity into the appropriate truck.

Review the FTL specifications above to see which truck could possibly accommodate this shipment.

Finding the Right Fit

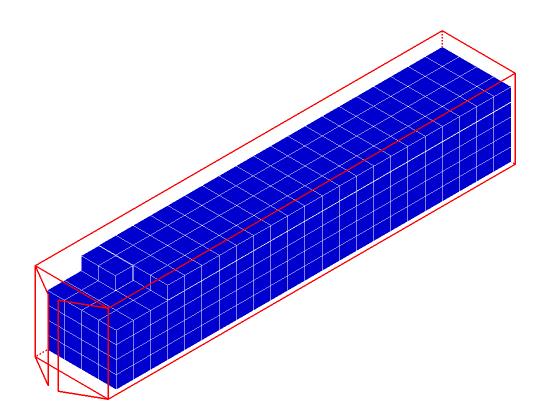

For this example, our shipment meets the usable capacity and payload weight requirements for a 48’ dry van. But let’s do some more calculating to ensure that we meet the height and width restrictions. Let’s plan on configuring the truck with 4 boxes across the width of the container, 23 rows across the length, and 5 stacks of boxes high, as shown in the figure below, and then calculate how much space our load will take up.

Start by multiplying the length of a single box by the number of rows of boxes stacked front to back to calculate the total length of the load. The answer for this example is 552”. Then convert the inches to feet by dividing the total inches by 12, for a total of 46 feet.

Start by multiplying the length of a single box by the number of rows of boxes stacked front to back to calculate the total length of the load. The answer for this example is 552”. Then convert the inches to feet by dividing the total inches by 12, for a total of 46 feet.

24 x 23 = 552 552 ÷ 12 = 46

Next, multiply the width of a single box by the number of boxes stacked in a row across the width of the truck to calculate the width of the load. The answer is 96”. Then convert the inches to feet by dividing the total inches by 12, for a total of 8 feet.

24 x 4 = 96 96 ÷ 12 = 8

Then multiply the height of a single box by the largest number of stacked boxes from the floor up to calculate the total height of the load. The answer for this example is 90”. Then convert the inches to feet by dividing the total inches by 12, for a total of 7 feet 6 inches.

18 x 5 – 90 90 ÷ 12 = 7.5

This configuration would take up 46’ length, by 8’ width, and 7’6” height, with a total weight of 13,500 lbs. Based upon these calculations and a review of the most popular FTL truck sizes, a 48-foot dry van, with interior dimensions of 47’4” length, 8’6” width and 9’2” height with a maximum payload of 45,000 lbs., is the most appropriate for the example above.

Considerations

- The specifications above are the industry’s averages, and equipment size or capacity may vary slightly.

- Usable capacity (volume) figures are based on a perfect load, with no empty space. It is impossible for most cargo to achieve these capacity figures.

- The limits stated above are the maximum allowed on U.S. roads. Heavier weight containers can be trucked, but special permits and equipment will be required.

- Load limits for trucking vary by country. Be sure to check the local requirements for your cargo’s and final destinations.

What if I don’t have enough goods to fill a full truckload?

Considering how much space is in a full truckload, clearly some businesses will not be shipping enough to fill an entire truck. If you have small items or are shipping smaller quantities, one option for you to consider is Less Than Truckload (LTL) shipping.

LTL shipping is when multiple businesses, who want to ship small volumes of freight less than 15,000 pounds, share a portion of a trailer. This means that, instead of paying for the entire truck, you only pay for the space that you use, making it a cost efficient method of shipping freight.

Fortunately, there are many other companies who want to ship their products in a consignment with other companies. Contact your OCEANAIR representative to see how we may assist you in consolidating your shipment.

Need Help?

Still having trouble figuring out what size truck is the best fit for your cargo? Feel free to contact your OCEANAIR representative. We will be happy to answer any questions you may have.